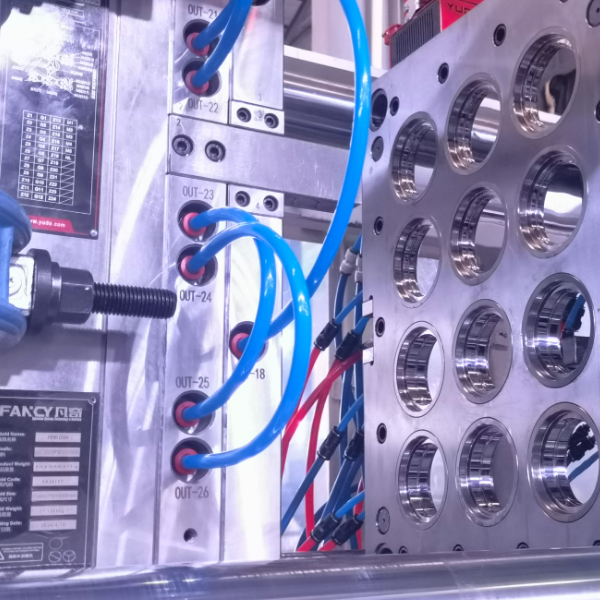

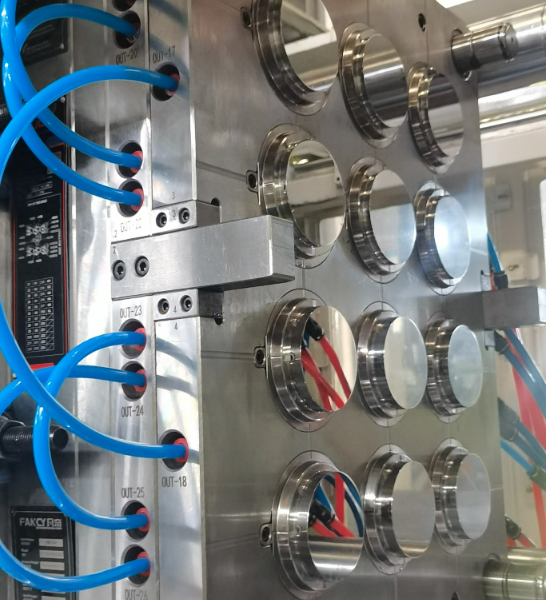

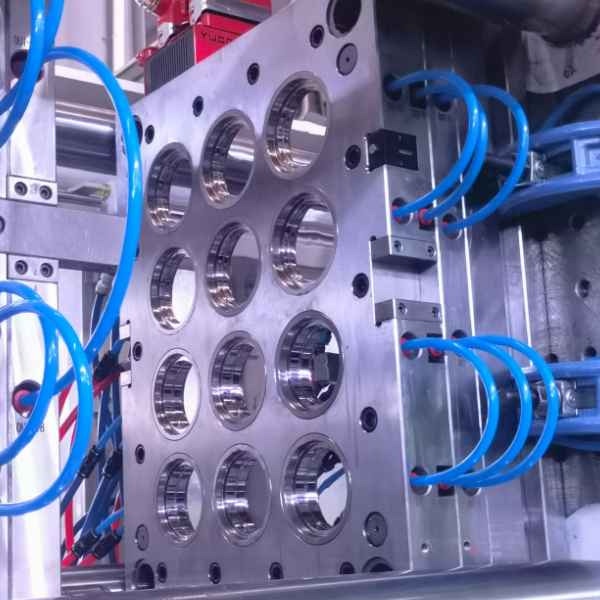

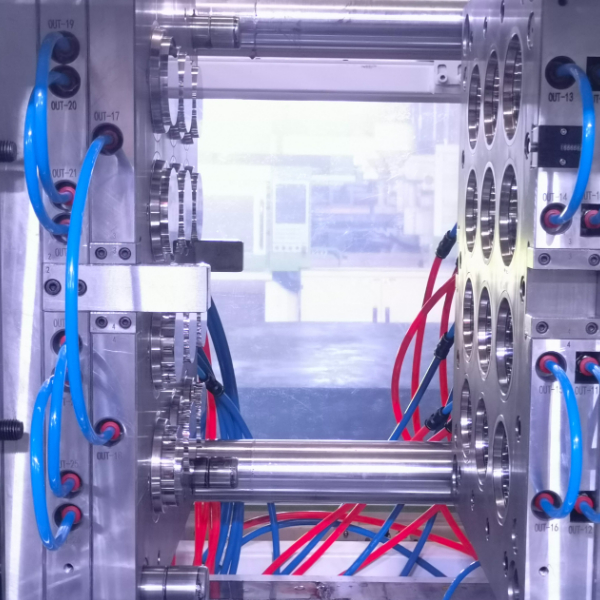

Petri Dish Tray Mold for Medical

Petri dish tray Molding Equipment

High speed injection PS petri dish tray mold light weight disposable design for PET & PS test Petri dish tray mold with injection cycle time within 10s. YUDO hot runner system and high production volume plastic molds

know more

Specification

| MOULD CAVITY | 6/12/16CAVITY |

| MOULD STEEL | S136 |

| HOT RUNNER | YUDO point gate |

| POWER | 380V |

| PRODUCT SIZE | 3 section/ 2section/ ventilation dish |

| MATERIAL | PS |

Descriptions

High speed injection PS petri dish tray mold light weight disposable design for PET & PS test Petri dish tray mold with injection cycle time within 10s. YUDO hot runner system and high production volume plastic molds.

12cavity, 16cavity Petri dish tray mold with high speed injection molding machine precision robot system and autaomation for assembly function.

Petri dish tray mold is insert interchangeable for various version base, such as 3 section petri dish tray, 2 section petri dish tray and ventilation lid.

Petri dish tray mold can be changed with new inserts in 30min. for high efficient working. PS material injection molding, need good mold temperature around 40degrees in the cavity, and 25 degrees in the core side. Mold is high polished, excellent smooth polish will be key of the petri dish tray mold.

Related Products

Get a Quote Now

Want a quote, you can leave your email and message here, our sales team will contact you in one hour.

Send Message